Preparing For A Physical Count

Before The Count:

-

Plan a meeting with your team ahead of time to go over the process. In this meeting, you should create two-man teams to count the inventory. You can assign each team to specific bin locations. If you have inventory spread throughout multiple stock sites, you can assemble specific teams to each stock site to conduct the count. The plan here is to have one person count the inventory while the other team member collects the data either manually on count sheets, or with a barcode scanner. Breaking the count into small groups eliminates your team members from becoming too overwhelmed at the thought of having to count thousands of items.

-

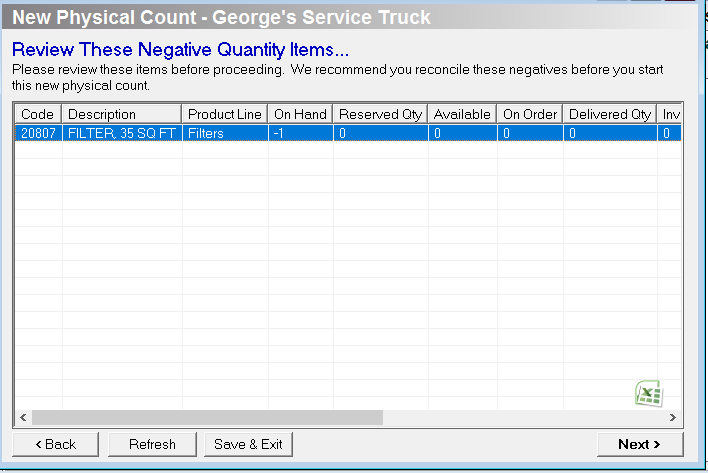

Review each of the “pre-physical count” screens presented prior to the count to ensure the least number of inventory write-offs. These screens include:

-

Items with negative quantity

-

ICPO items in transit

-

Items in pending return queue

-

Items delivered but not invoiced, or items invoiced but not delivered

-

Open orders

-

Open job materials

-

Items on open Vendor PO’s

-

Remove any defective items from your inventory so they are not part of the count.

-

Make sure you are closed during the days (or times) you are conducting your physical counts. Conducting business during this time can cause discrepancies in your count.